3M: Fostering Sustainability Within a Circular Economy

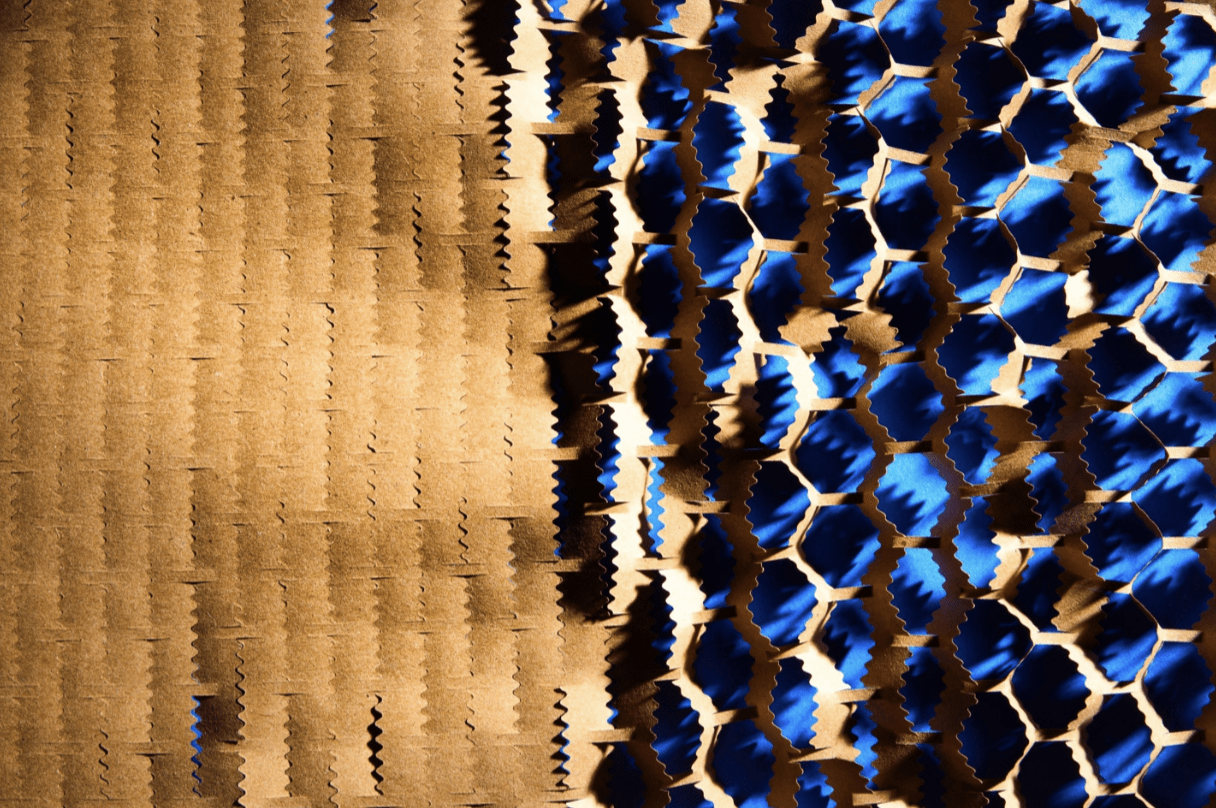

3M’s Cushion Lock™ protective wrap: a sustainable alternative to bubble wrap/3M

3M’s Cushion Lock™ protective wrap: a sustainable alternative to bubble wrap/3M

By Dr. Marie-Claude Brandys

September 16, 2024

According to the United Nations, the world’s population is more than three times larger than it was in the mid-20th century and it is expected to increase by nearly two billion people in the next 30 years. This rapid growth brings with it urgent challenges, including limited natural resources, food scarcity, rapid urbanization, and climate change. These challenges demand innovative solutions and a concerted effort to ensure a sustainable future for generations to come.

At 3M Canada, we are committed to driving progress in our environmental, social, and governance practices with a strong focus on advancing sustainability. Beginning in 2019, 3M has promised that every new product that enters the new product commercialization process must have a Sustainability Value Commitment demonstrating how it drives impact for the greater good.

A Sustainability Value Commitment in new products is a clear demonstration of how the products integrate environmental and social factors to contribute to our aspirations. This can include reusability, water savings or responsible sourcing. It can also include products whose core purpose helps to solve an environmental or social problem – such as improving air quality or reducing greenhouse gas emissions.

Central to our sustainability efforts is the pursuit of a circular economy, where materials are reused and repurposed, reducing waste and their impact on the environment.

Creating a Circular Economy

Climate change is affecting us all. Extreme weather events, rising sea levels, and other environmental impacts are shaping the daily decisions that we all make. We recycle and compost, conserve water and electricity, but we cannot do it alone. In today’s era of growing environmental concerns, manufacturers especially have an important role to play. The goal is to do more with less, keeping products and materials in use longer, and reducing or eliminating waste and pollution.

Among other things, the COVID-19 pandemic accelerated the shift to online shopping due to government restrictions and consumer health concerns. As online shopping surged, so did the need for sustainable materials to minimize packaging waste and environmental footprints. Designing packaging with both consumer needs and environmental impacts in mind became increasingly critical during this time.

A prime example of this is the Scotch™ Cushion Lock™ Protective Wrap. Made from 100% recycled paper, this innovative product is a sustainable alternative to traditional plastic bubble wrap that maintains the same level of protection as plastic packaging material.

Unlike conventional plastic bubble wrap, which has been the industry standard for decades, Cushion Lock™ expands up to 60 times its original volume to fill packing boxes efficiently with less material. Once the product has done its job, it can easily be recycled with other curbside materials, such as plastics, cardboard, or glass.

Circular Packaging

Today’s complex global supply chain, along with 3M’s product diversity and markets, means there is no one-solution-fits-all approach for product packaging. Our proprietary Packaging Sustainability Roadmap places a special focus on circular package design, providing a toolkit for our packaging engineers that defines circularity terms and highlights which packaging materials to select for specific outcomes, such as designing for reusability and recyclability, increasing recycled content, or transitioning to renewable materials. The toolkit includes a Packaging Recyclability Guide, which references global industrial aids and presents them in an easy-to use format that simplifies selection of recyclable materials.

3M package engineers use this toolkit as a guide to help them make key design decisions that reduce or eliminate packaging where possible and improve our packaging circularity. These efforts have resulted in a weight reduction of 198 metric tonnes of packaging material and the elimination of 104 metric tonnes of virgin fossil-based plastic.

3M has a variety of sustainable packaging solutions, and we are constantly innovating to do more. Our sustainable packaging innovation can be seen across 3M product lines such as the recent redesign of our Command™ Picture Hanging Strips in our North American market. The new packaging replaces the plastic blister packs with paperboard cartons made from 100% recycled fibres with 35%–60% post-consumer recycled content. This eliminated over 43.5 metric tonnes of plastic while improving packaging recyclability.

Product and packaging innovation starts with responsible sourcing, a commitment 3M takes to heart.

Forest Product Sourcing

As a global paper purchaser and sustainability leader, 3M believes we can positively influence practices throughout the forest products supply chain. Our 3M Forest Products Sourcing Policy sets standards of excellence for our suppliers through all tiers of supply.

We expect all forest products from our suppliers to contain materials that are legally harvested, sourced, transported, and exported from their country of origin. In addition, we expect all suppliers to work to ensure that virgin-wood fibre supplied to 3M is traceable, is harvested in a way that maintains or enhances high conservation values and is free of deforestation.

To support our policy, we partner with Earthworm Foundation, a global nonprofit working with companies, farmers, nongovernmental organizations, and governments to create solutions that serve people and regenerate nature. Along with Earthworm Foundation, we’re supporting the Tsay Keh Dene (TKD) First Nation in British Columbia to protect high conservation value forests in their territory. As some of the world’s last remaining intact forests, they serve as sources of sustenance, culture, and history for the TKD, as well as critical species habitat and carbon storage.

Innovating for a Sustainable Future

Looking ahead, we have set ambitious targets to do our part in building a more sustainable future. By 2030, we aim to reduce carbon emissions by 50%, followed by an 80% reduction by 2040, and ultimately striving to be 100% carbon neutral by 2050. Globally, we have invested approximately $1 billion over 20 years dedicated to achieving carbon neutrality.

We are committed to reducing water use at our facilities by 25% and returning higher-quality water to the environment after it is used during our manufacturing processes.

As part of our mission to achieve our sustainability goals, we have also partnered with organizations such as Svante, Carolinian Canada and Earthworm Foundation. Through these partnerships, we can leverage each other’s strengths and resources to help solve some of the biggest sustainability challenges in Canada and beyond.

3M believes that collaboration can drive us all forward and we remain committed to working with our customers, our suppliers, and our partners to tackle the climate challenges we all face.

Dr. Marie-Claude Brandys is 3M Canada Country Governance Leader and Director of 3M’s Area Product Stewardship Centre of Excellence.